“Back Forty Tailings Facility ‘Not a Pond,’ Aquila Says”?

Response by the Mining Action Group

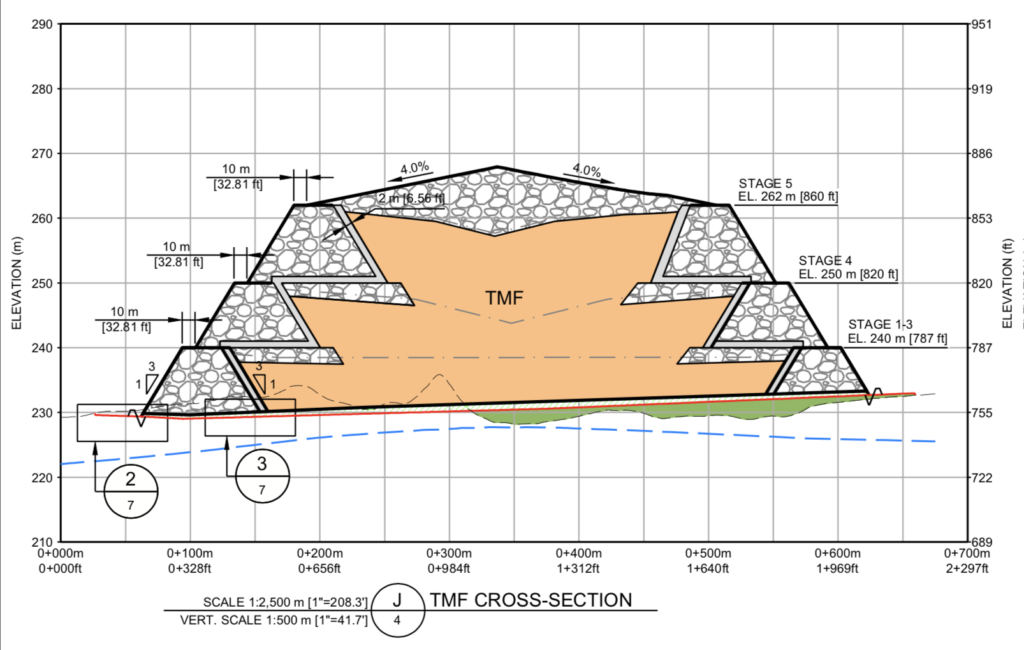

The Aquila Back Forty’s Mining Permit amendment, under consideration by the Michigan Department of Environmental Quality, features a tailings dam (aka “tailings management facility”, or TMF) to be built using the extremely risky “upstream” method. Objections to the Back Forty’s TMF design have been raised by numerous environmental groups, including the Mining Action Group of the Upper Peninsula Environmental Coalition, Menominee River Front 40, the Coalition to Save the Menominee River, the Center for Science in Public Participation, the Wisconsin Resource Protection Council, the Michigan Environmental Council, and others.

The upstream tailings dam method is designed to fail, environmental groups warn. Industry experts consider the upstream method to be the least desirable type of tailings dam construction, due to its high risk of dam instability.

It is used because it is cheaper to construct, but is not the “Best Available Technology”. TMF dam walls are “raised” and each successive raise is partially supported by tailings, as depicted in the Back Forty TMF diagram above. This design is fundamentally unstable, and part of what makes the “upstream” construction method especially risky. The upstream dam method has been banned in several countries.

A POND IS NOT A POND, SAYS AQUILA?

Aquila’s public relations manager, Dan Blondeau, is trying to assure concerned citizens that the Back Forty’s upstream tailings dam won’t fail. In correspondence with filmmaker Mark Doremus, Blondeau claimed the “Back Forty tailings facility is NOT a pond and will NOT store liquid tailings.”

“I’d say Blondeau should read the permits,” said Kathleen Heideman of the Mining Action Group.

“The Back Forty tailings WILL be pumped as a wet slurry. These WILL be liquid tailings,” said Heideman. “The Back Forty tailings facility WILL contain a pond.”

The permit amendment makes it clear that wet tailings, deposited in the TMF structure, will be topped by a huge pond – water from the tailings:

- “The decant pond expands from 100,000 cubic meters (m3) capacity to a maximum of 150,000 m3, then diminishes to 50,000 m3 at the end of operations”

- “The height of the decant pond will rise as the TMF is constructed, with a maximum height of 36 meters at full build-out”

It may be hard to visualize the size of that pond, but “150,000 m3” (cubic meters) means the decant pond will be roughly six times larger than the Lincoln Memorial Reflecting Pool in Washington DC. [1]

In the Aquila Back Forty Dam Safety Permit, the volume of “supernatant water” (floating on the surface of tailings) is predicted to be even larger – almost 40 million gallons:

- “The maximum volume of supernatant water allowed in the (tailings) decant area will decrease with time from 0.15 Mm3 (39.6 Mgal) to 0.05 Mm3 (13.2 Mgal)”

40 million gallons of water – how big is that?

- “A good-sized bath holds 50 gallons, so a million gallons would be 20,000 baths” [2]

The Back Forty TDF pond will hold enough water to fill 800,000 baths. - “An Olympic-sized swimming pool holds 660,000 gallons of water” [3]

The Back Forty TDF pond will hold enough water to fill 60 Olympic swimming pools.

Blondeau claimed the Back Forty tailings dam has a “maximum projected height of 130 feet” but the permit states a maximum projected height at closure of “42 meters” (138 feet tall). How tall?

- A mature white pine tree averages 50 to 80 feet tall.

- At 138 feet, the Back Forty tailings dam will be 55% taller than Marquette’s Landmark Inn (89 feet tall).

WILL ADDITIONAL TAILINGS STORAGE BE NEEDED?

The Back Forty tailings facility will cover 124 acres of the mine site.

“Blondeau fails to acknowledge the monstrous size of the Back Forty tailings dam,” said Heideman. “124 acres of tailings – that’s like 50 city blocks, or 100 football fields. Tailings will cover an area 25 times larger than the Superior Dome at Northern Michigan University,” said Heideman.

And that may be just the beginning. The Mining Action Group has questioned whether Aquila is being honest in calling the Back Forty project a “7 year open pit mine” operation. Environmentalists believe that Aquila is planning an underground mining phase, although the permit applications deny that any underground mining will take place.

From 2015 until early 2018, Aquila Resources described the Back Forty project as having a “16 year life of mine and mill of 16.1 Mt of ore, including both open pit and underground mining.” This claim was repeated in Aquila’s press releases, investor statements, in presentations to the local community, and in correspondence with the Michigan DNR and the Menominee Indian Tribe of Wisconsin. In 2016, Aquila told their investors they would submit an underground permit once the open pit mine and milling facility were operating. Now the applicant is winking, telling investors that underground expansion will require “additional studies…”

Environmental groups claim that Aquila will pursue additional 9 years of underground mining, for a total of 16 years of mining. If true, the TMF will need to “accommodate” additional waste.

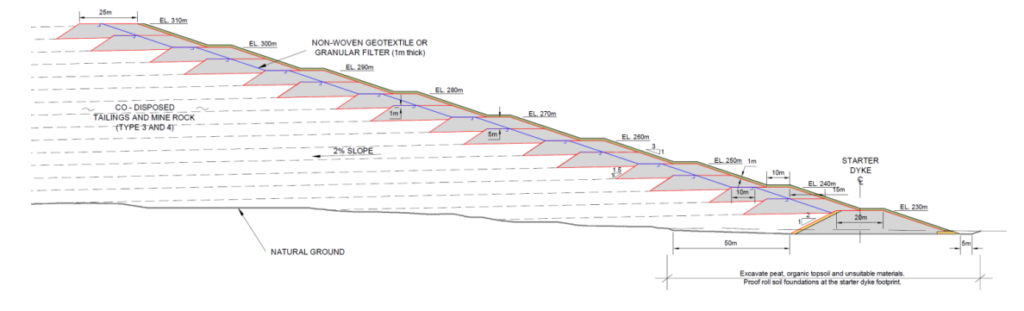

That’s the reason why mining companies build “upstream” tailings dams – the structure can “grow higher” if the mine needs to store more waste. TMF impoundments are frequently expanded through additional raises, which greatly increases the height of the dam walls and the total volume of waste rock and water contained within the structure. This habit of incremental raising greatly exacerbates the problem of instability, and has resulted in the catastrophic collapse of several tailings dams.

Strict impoundment loading limits were not defined in the Back Forty mine permit amendment application. It is reasonable and foreseeable to assume that Aquila has selected the controversial “upstream dam” method because it could allow for sequential expansion through raising of the dam wall (as pictured above) What may begin as a TMF with “three raises” can grow exponentially via incremental change, if permitting review is not environmentally protective. The tailings dams at Brumadinho and Mount Polley were raised higher than originally designed, multiple times.

PERMANENT WASTE STORAGE

“Instead of talking about 100 year rainfall events, we need to be thinking about a 10,000-year lifespan,” said Heideman. “What are the real storm risks, the real seismic risks, the groundwater risks from failure of materials with a limited life, like the plastic liners underneath the TMF?”

When the risks are properly calculated for a 10,000-year lifetime – the figure often used for how long these tailings structures will need to maintain their integrity – experts say there is “a significant and disproportionate chance of failure for a tailings dam.” [4]

“TRIED, TESTED, AND PROVEN”?

Blondeau claims that the design of the Back Forty TMF “uses tried, tested, and proven engineering methods” because “similar facilities are already in operation at the Malartic Mine and the MusselWhite Mine in Canada, and the Neves Corvo Mine in Portugal.”

These mines – Malartic, Musselwhite, and Neves Corvo – offer proof of nothing. “Thickened tailings” have been used for less than 10 years. The type of ore, tailings, and method of disposal varies widely – and the TMF designs are very different:

Malartic Mine

The Malartic Mine has only been operating since 2011. Malartic’s tailings are non-reactive. The thickened tailings have “solid material concentrations of between 65 and 70%” with “little or no free water. They form cone-shaped cells of various heights. The tailings are used to “cover acid-generating tailings” (to a depth of 3 meters), to remediate a previously abandoned tailings impoundment. To “avoid overflows, a sterile stone wall will be built around the various cells.” This is significantly different from the Back Forty TDF, where tailings will be highly reactive, tailings will decant a large quantity of water, and TMF walls will be built using reactive waste rock, not “sterile stone.” [5]

Musselwhite Mine

The Musselwhite Mine in Northwestern Ontario went into production in 1997 and “began thickened tailings disposal in May 2010.” “The cold climate presents a special challenge to operating the thickened tailings system as there is very little precedent experience.” To reduce the likelihood of acid generating and metals leaching in the long term, the Musselwhite Mine announced plans “to remove the sulphide minerals from the tailings stream using a flotation plant.” Construction of a tailings thickener began in 2009; this was done to “to allow for an increased life span (capacity) of the current tailings management area. The thickener will reduce the water content in the tailings to approximately 74% solids to allow for stacking/mounding of the dry tailings…” [6] This is significantly different from the Back Forty TDF, where tailings are highly reactive, sulfides are not removed, and tailings are not “dry” or “stacked.” [7]

Neves Corvo Mine in Portugal

Owned by Lundin Mining, the Neves Corvo Mine opened in 1988. “Neves-Corvo has been developed as an underground operation, exploiting a number of polymetallic sulphide orebodies” with“tailings from the mine stored into a 190 hectare tailings management facility (“TMF”) bounded to the north by a rockfill embankment across a natural river valley. The facility was originally developed for subaqueous tailings deposition, but converted to thickened tailings deposition in 2010 “with an accompanying thickened tailings plant to increase the storage capacity.” At Neves Corvo, due to “multiple expansions of underground mining” and “expansion of the zinc processing plant and the volume of tailings produced, there will also be a need to expand the tailings thickening plant.” Additionally, underground “voids are being backfilled using a mixture of development rock, cement, and “paste fill (PF) made from cycloned process tailings.” This is different from the Back Forty TDF: Neves Corvo uses an upstream tailings dam [8] but the disposal of thickened tailings (begun in 2010) has not solved their tailings storage problems: new mining and “expansion of the zinc processing plant” resulted in yet more tailings; a new “Feasibility study for expanding the TMF… will provide a comprehensive tailing development scenario.”

Read that again: after 30 years of mining, Lundin is still trying to come up with a “comprehensive tailing development scenario” for Neves Corvo Mine? Ever-expanding operations come with demands “for additional tailings and mine waste rock storage at the Neves Corvo tailings storage facility, beyond the 2015 deposition design. Specifically an increase of up to 27 Mt of tailings and as much as 10 Mt of mine waste rock need to be accommodated…” [9]

That’s exactly what must be avoided at the Back Forty.

In all these mines, “thickened” tailings management was used to address “capacity problems” caused by expanding mining operations – suggesting these mines were not carefully planned, or failed to disclose future mining phases, resulting in undersized tailings storage. Mining companies treat TMFs like magic garbage bins, which must expand on demand to “accommodate” whatever amount of tailings and waste is produced.

FILLED WITH REACTIVE WASTE

The Back Forty is a polymetallic orebody. After processing, the finely ground tailings will contain hazardous metals cable of producing acid mine drainage and mobilizing metals through leaching. Geochemical modeling provided in Aquila’s 2015 application demonstrated that 77% of the waste rock and nearly all ore is reactive. The leachate produced by geochemical analysis of Back Forty tailing samples had an average pH of 2.5, very acidic.

All tailings held inside the TMF will be reactive, at risk of acid mine drainage. Recent tailings dam collapses, like the Brumadinho tailings dam in Brazil and the Mount Polley tailings dam in Canada, resulted in catastrophic environmental damages but their tailings were either inert or less reactive.

Blondeau downplayed the hazardous nature of the Back Forty tailings, comparing them to “toothpaste” and “drywall mud.”

In fact, the Back Forty’s tailings will be more toxic than either Brumadinho or Mount Polley.

“Mr. Blondeau’s comparison of the consistency of the dewatered tailings to ‘drywall mud’ or ‘toothpaste’ is not reassuring when you consider that with the ‘upstream’ design these mudlike materials end up being a structural part of the dam!” said Steve Garske of the Mining Action Group. “The remaining water in the tailings is what causes these dams to fail.”

Heideman calls the comparison with drywall mud and toothpaste “insulting.”

“There is no beneficial reuse. There is nothing domestic or healthy about it. These are toxic industrial tailings, full of mercury, lead, cancer-causing metals, acid-generating sulfides, residual sodium cyanide, chemical frothing reagents used in the milling process, and more. Failure of the Back Forty’s upstream tailings dam, whether it happens in five years or five hundred, would be an unspeakable environmental catastrophe.”

DESIGNED TO FAIL

Upstream mine tailings dams have been called “bombs waiting to explode” – and they are collapsing. The “failure rate of tailings dams has remained at roughly one failure every eight months… Over a 10,000-year lifespan (a figure often used for how long these structures will need to maintain their integrity) this implies a significant and disproportionate chance of failure for a tailings dam.” [10]

“This is really the mining industry’s dirty secret: upstream tailings dams are cheap, risky, and unstable,” said Heideman. “The State of Michigan cannot allow the Back Forty project to proceed as designed.”

NOTES

- https://www.bluebulbprojects.com/MeasureOfThings/results.php?comp=volume&unit=cm&amt=100000

- https://water.usgs.gov/edu/mgd.html

- https://en.wikipedia.org/wiki/Olympic-size_swimming_pool

- https://ofmpub.epa.gov/eims/eimscomm.getfile?p_download_id=513583

- http://www.mining.com/malartic-gold-mine-class-action-lawsuit-trial-begins/

- http://csr.goldcorp.com/2010/docs/2009_musselwhite.pdf

- https://papers.acg.uwa.edu.au/p/1104_21_Kam/

- https://www.lundinmining.com/site/assets/files/3643/neves-corvo-technical-report.pdf

- https://papers.acg.uwa.edu.au/p/1504_40_Lopes/

- https://ofmpub.epa.gov/eims/eimscomm.getfile?p_download_id=513583